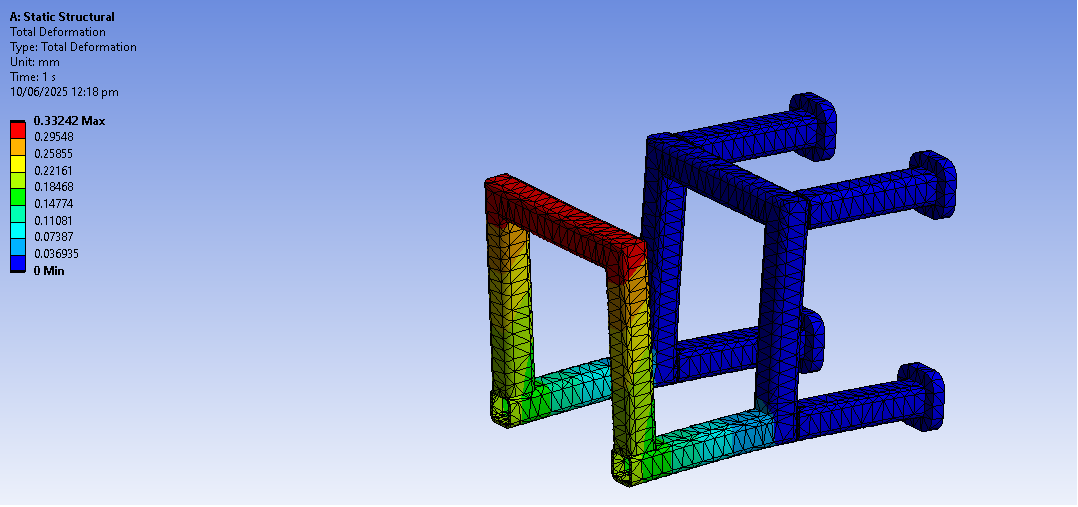

Design decisions move faster when you can validate performance early. Finite Element Analysis (FEA) helps engineers evaluate strength, stiffness, deformation, and safety factors before committing to prototypes or tooling. With professional FEA analysis services, your team can reduce trial-and-error, focus on the most promising concepts, and move through design reviews with greater confidence. SEACAD Technologies supports engineering teams with simulation expertise that turns design questions into clear, actionable results.

Why FEA Matters in Modern Engineering

FEA is more than a check at the end of design—it’s a way to guide better decisions throughout development. When loads, constraints, and material behavior are understood early, engineers can optimize weight, reduce overdesign, and identify risk areas before they become costly changes.

Benefits of FEA Analysis Services

- Faster validation without repeated physical builds

- Early visibility into stress concentrations and deflection

- Better confidence during internal and customer reviews

- Improved design quality with fewer late-stage revisions

- Clear documentation to support engineering decisions

What SEACAD FEA Analysis Services Typically Include

A strong simulation outcome depends on both software skill and engineering judgment. SEACAD’s approach focuses on understanding the design intent, building a reliable model, and presenting results in a way that supports decisions.

Core Steps in a Practical FEA Workflow

- Define objectives, loading conditions, and acceptance criteria

- Review geometry, materials, and contact assumptions

- Build and refine the mesh for reliable accuracy

- Run analysis and perform reasonableness checks

- Interpret results and highlight design improvement options

- Provide a concise report that supports next actions

FEA can support static structural checks, linear and non-linear behavior (as applicable), and comparative studies between design variants, depending on project requirements.

When Electrical and Mechanical Systems Interact

Many products combine mechanical structures with electrical components, and design changes in one area can affect the other. While FEA focuses on structural behavior, understanding system-level constraints is important when routing, enclosures, and mounting features are involved. Teams that use SolidWorks Electrical often benefit from simulation support that considers the practical realities of wiring space, connectors, and hardware integration—helping mechanical designs stay compatible with electrical intent.

Using SOLIDWORKS Simulation to Support Faster Decisions

For organizations working within a SOLIDWORKS environment, SOLIDWORKS simulation can be an efficient way to evaluate designs without switching tools or rebuilding models elsewhere. When set up correctly, it supports quicker iteration and clearer communication between designers and analysts. SEACAD can assist by running simulations, reviewing model setup, or advising on best practices so teams avoid common pitfalls like unrealistic constraints or misinterpreted results.

Choosing the Right Simulation Partner

FEA is only useful when the assumptions match reality and the results are interpreted responsibly. A good partner helps you ask the right questions, select the correct analysis approach, and translate outputs into engineering decisions.

What to Look For

- Engineering-focused interpretation, not just colorful plots

- Clear documentation of assumptions and boundary conditions

- Practical design recommendations, not only pass/fail outcomes

- Communication that supports your design and manufacturing teams

Get Started with SEACAD Technologies

If you want to validate designs faster and reduce risk before production, SEACAD Technologies can support you with professional FEA analysis services. Contact us to discuss your requirements and receive a simulation approach tailored to your product and timeline.